Foundry

At Mahasai Aluminium, we adhere to specific chemical compositions for manufacturing logs to ensure the premium quality and durability of products with the aid of the latest hot-top casting technology.

Raw material and alloying elements are procured from primary producers. Ingots are melted and the process of alloying is carried out in melting furnaces. The liquid metal is then tested instantaneously in a computerized spectrometer to ensure that the alloy composition complies with global standards. The treated liquid molten aluminum is cast in a hot-top casting system which ensures precision casting with a high degree of grain uniformity.

Extrusion

Extrusion

At Mahasai Aluminium, we have deployed a state-of-the-art manufacturing facility to produce products of impeccable quality. It starts with pre-heating Homogenised logs and feeding them into the container for the process of extrusion with the aid of an automated PLC control system.

The application of heat and tremendous pressure forces the solid aluminium through the opening of the extrusion die to ensure a high degree of structural stability. The extruded Aluminium profiles are handled on PLC controlled conveyor system to avoid any sort of scratches, or dents on the product. Manual hand contact is avoided throughout the entire process.

The extruded profiles are stretched to enhance the straightness & stability and to relieve internal stresses. Mahasai Aluminium is involved in manufacturing aluminium extrusions of different alloys depending on the application and customer’s requirement, completely providing a detailed solution for the end use, these include aluminium alloys of series 1XXX, 2XXX, 3XXX, 5XXX, 6XXX, 7XXX and in tempers M, O, T4, T5 & T6.

Tool Room

Dies & toolings required for the manufacturing of aluminium extruded profiles are procured from approved vendors equipped with computer-aided manufacturing facilities such as Wire Cut, CNC Milling & CNC Machining

Centres. They are manufactured with imported hard die steel (H13) which is subsequently heat-treated to ensure high wear resistance. Frequent nitriding process of dies is ensured to improve the hardness and better surface finish

of extruded profiles.

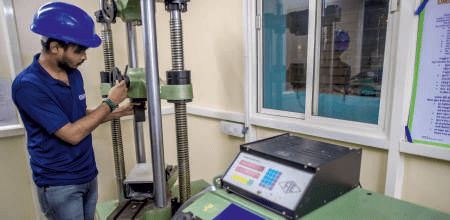

Quality and Inspection LAB

Mahasai Aluminium Profiles Private Limited is committed to providing a quality product that meets the requirements of contract specifications to enhance customer satisfaction. We believe in quality beyond everything. We have undertaken stringent quality checks to ensure products are of global standards. The entire process is monitored with utmost care and attention at every stage. We use premium quality raw materials from primary sources so that the product is more durable and lasts longer. In addition to this, we are

equipped with high-end analytical equipment to meet international standards and equipped to supply material as per IS/ DIN/ ASTM/ EN/ BS international standards or as per customer specifications subject to the designed constraints.

All extruded profiles are subjected to various destructive & non-destructive test in various equipment which include:

Computerized Spectrometer for metal analysis.

Electrical conductivity meter

Computerized Universal Testing Machine to analyze mechanical properties of finished goods

Webster, Hardness Testers